Name: Double head sleeve Labeling Machine TB-D250 1 SET

Country: Indonesia

Industry: Beverage

Details: This factory specializes bottle juice,water products, our double head labeling machine mainly label for this PET bottle body and neck at same time

Name: Double head sleeve Labeling Machine TB-D250 1 SET

Country: Indonesia

Industry: Beverage

Details: This factory specializes bottle juice products, our double head labeling machine mainly label for this PET bottle body and neck at same time

Double head sleeve labeling machine is two in one machine, it adopts unique double label-feeding frame to provide film and label for bottle neck and body. it will save cost and space for customer and also improve whole production efficiency.

It adopts rotary potentiometer which enables label feeding stable and fluent and avoid the error label length, label block and other problem

Stable clean down unit. It adopts motor and double circular arc synchronous belt makes clean down plastic core-rubber-tires synchronously and ensures the label casting stably. Especially inhibiting device on bottle divider effectively control the fault operations and ensures the safety of the center pillar.

High-precision,high quality label-cutting process. The new style cutting knife drived by servo motor, with high speed, more stable and precision. Synchronous fiber electricc eye enables the tolerable error to less than ±1mm.Cutter head design which apply to the container of ∮30mm—∮130mm.You never need to change or debug it. Original sensor is inside the cutter head and when you take down cutter head, you dont need to correct the synchronous belt. It also has unique light touch human-machine screen, that means, auto search original location as well as safety and convenience.

Easy to adjust bottle-carrying position. Adopted with mechanical transmission to drive the positioning belt on both sides.While changing the whole bottle carrying unit, the down and up, width are all controlled by one handwheel aiming to synchronously and swiftly adjust.

Accurate label position. When conveying bottle in high speed, It will make sure right label location according to adjusted belt place and brush unit. Low error rate, stable and high efficiency

Automatic system control, better human- computer interaction LCD touch screen design and intelligent operating system(PLC control) will make sure machine feedback quick and accurate.

Double Head Labeling Machine applies to food & beverage industries as fruit juice bottle labeling, tea bottle labeling, drink bottle labeling, dairy products bottle labeling, pure water bottle labeling, condiments bottle labeling, beer bottle labeling and sports drink bottle labeling etc. Of all kinds of bottles; It's suitable for various kinds of bottle types and bottle material, for example: round bottle labeler, square bottle labeler, flat bottle labeler, curved bottle labeler and cup-shaped labeler, plastic bottle labeler, glass bottle labeler etc.

Double head sleeve label applicator can label for bottle neck and body at same time. two in one machine can save space and cost, improve production efficiency and have perfect shrinkage effect.

1. It can label bottle body and neck at the same time, which can reach max. capacity of 2*450 bottle per minute.

2.The machine can be used in two ways. It not only reduces a a trapping label machine, but also proves as cost effective for our clients;

3. It reduces the length of conveying line and avoids the secondary transportation , so that it increase the production efficiency and the capacity of floor area. Of the equipment.

4. It also reduces stumbles in the process and increase the quality of product.

5. It adopts equivalent PLC, positioning module, servo motor and frequency converter. In addition, its touch screen is featured with a humanized operation.

Below machine (steam shrink tunnel, electric shrinking tunnel, steam generator and conveyor)can be connected with double head sleeve labeling machine, Customer can choose for yourself according to your needs.

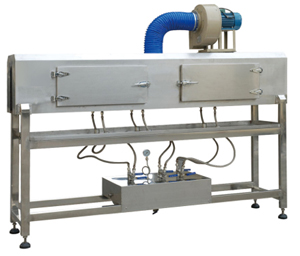

Steam shrink tunnel improve the efficiency highly. The adjustment and maintain is convenient, the shrink is in order. The spout of steam use the separation style which make the tunnel smooth. The spout mouth is divided into four parts and the height ,place and quantity of steam of every part can be adjusted in order to make the shrink effect perfect .The low pressure steam bag use the seamless steel tube design and every connect tube use stainless steel soft tube ,so the disassembly and fixing is very convenient. The whole machine is made of stainless steel, so it is heat preservation and save energy sources. Besides, it accord with the international safety standard. The stainless steel plane at the bottom can condensate water and drainage them and working environment cannot be influenced. There are two eye window in front and at the back of the box body. The waterproof design of the whole machine is made of stainless steel which makes the operation and maintain convenient.

New hot air shrinking tunnel: It adopts high pressure blower machine. Special designed hot air circle tunnel saves more energy and make the shrinked bottle more beautiful. Compare with the traditional shrinking tunnel, this kind of tunnel can do better for curved bottle.( optional).

Steam generator use LCD Automatic Intelligent Electronic Control System

The boiler operating system is automatically controlled, and all running state can be seen on the LCD screen. You could observe on the display screen the working state of boiler electric heating pipe, boiler water level state, level of steam pressure, pump running state as well as fault and alarm state etc, making you know the operating condition of the boiler at any time, and use at ease.

This kind of conveyor belt is used in the beverage production lines. It is used to convey glass bottles or the fully-filled plastic bottles. The length and width as well as material of this conveyor can be made according to clients' requirements.